Measuring the condition of the lubricant in an engine contributes to maintaining engine efficiency and longevity. TBN (Total Base Number) and TAN (Total Acid Number) are key indicators in engine oil, particularly for monitoring the health and performance of the lubricant.

Understanding TBN

A lubricant is exposed to acidic substances throughout the combustion process. These acidic substances attack the metal surfaces as well as the oil itself. Therefore, a lubricant must be able to neutralise them thanks to the special additives contained in its formulation. This neutralisation capacity is measured through the BN (Base Number), or TBN (Total Base Number). Expressed in milligrams of potassium hydroxide per gram of oil (mg KOH/g), TBN serves as an indicator of the amount of base reserve additive available to neutralise acids. In use, the TBN value of oil decreases gradually, meaning that the oil loses its ability to protect against corrosion.

TBN plays an important role in the qualification of lubricants, where it is referenced by international organisms, as i.e., ACEA and API, and Original Equipment Manufactures (OEMs) , for fresh oil standards. In the Eni product data sheets, the BN/TBN is typically listed in the characteristics section of the document. The method generally used to measure TBN is ASTM D 2896 -the Standard Test Method for Base Number of Petroleum Products by Potentiometric Perchloric Acid Titration.

Why is TBN important?

Understanding Total Acid Number (TAN)

TAN is a measure of acidic organic constituents that are present in lubricants detected by means of a basic reagent (potassium hydroxide or KOH). TAN is the quantity of base, expressed in milligrams of potassium hydroxide, which is required to neutralize all acidic constituents in 1 g of sample.

For used oil, TAN can increase as a result of the oxidation process that occurs during the service of lubricating oil.

Why is TAN important?

Why Both Indicators are Important?

In practice, both TBN and TAN measurements are necessary for preventive maintenance in engines, particularly in heavy-duty or high-performance applications.

By using TBN and TAN data, maintenance teams can make informed decisions about oil change intervals. This can potentially extend the oil's usable life, reduce unnecessary oil changes and therefore save costs while reducing environmental impact.

If you are interested in learning more, please contact our technical advisor or sales representative.

Understanding TBN

A lubricant is exposed to acidic substances throughout the combustion process. These acidic substances attack the metal surfaces as well as the oil itself. Therefore, a lubricant must be able to neutralise them thanks to the special additives contained in its formulation. This neutralisation capacity is measured through the BN (Base Number), or TBN (Total Base Number). Expressed in milligrams of potassium hydroxide per gram of oil (mg KOH/g), TBN serves as an indicator of the amount of base reserve additive available to neutralise acids. In use, the TBN value of oil decreases gradually, meaning that the oil loses its ability to protect against corrosion.

TBN plays an important role in the qualification of lubricants, where it is referenced by international organisms, as i.e., ACEA and API, and Original Equipment Manufactures (OEMs) , for fresh oil standards. In the Eni product data sheets, the BN/TBN is typically listed in the characteristics section of the document. The method generally used to measure TBN is ASTM D 2896 -the Standard Test Method for Base Number of Petroleum Products by Potentiometric Perchloric Acid Titration.

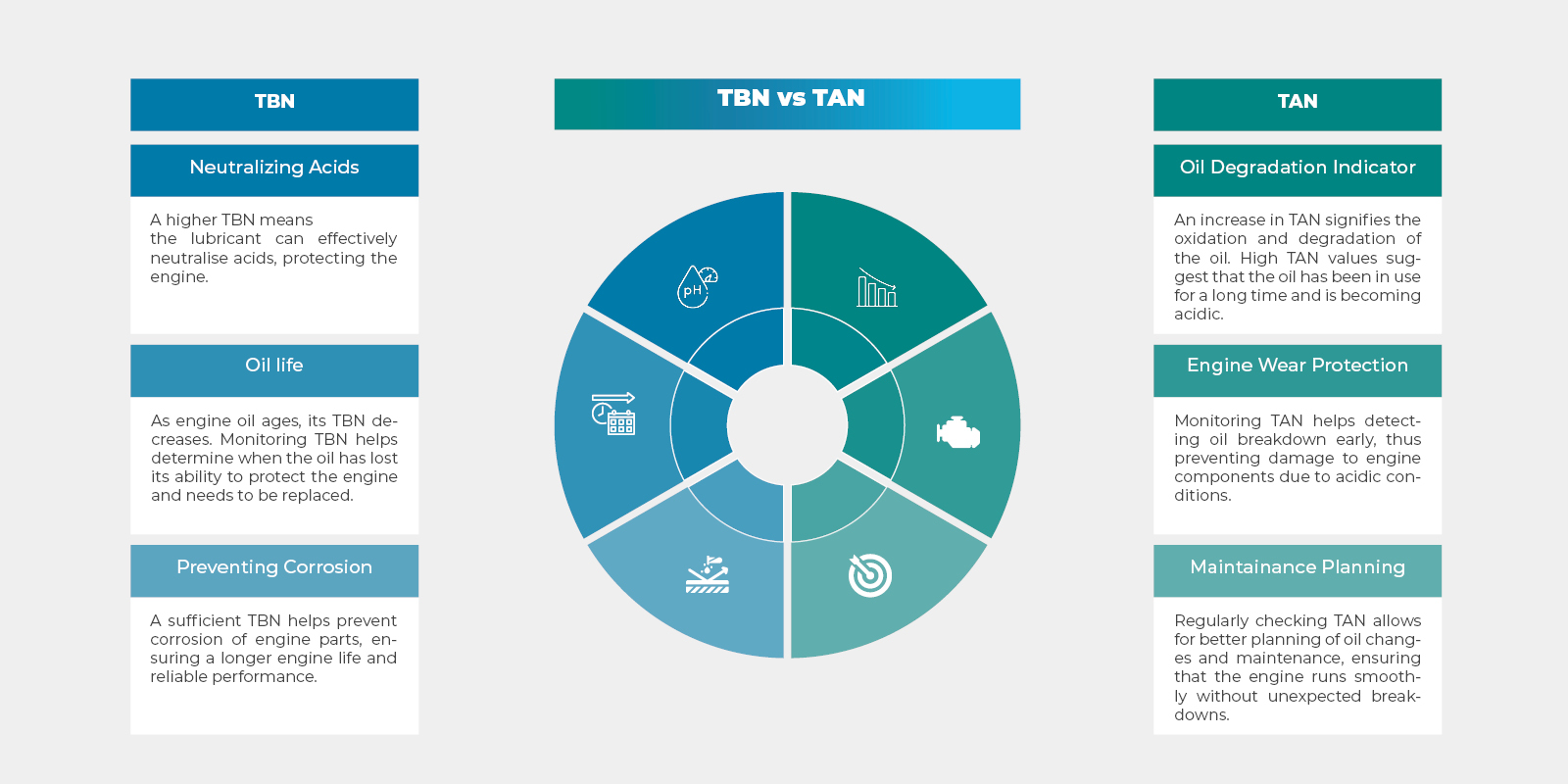

Why is TBN important?

- Neutralizing Acids: A higher TBN means the lubricant can effectively neutralise acids, protecting the engine.

- Oil Life: As engine oil ages, its TBN decreases. Monitoring TBN helps determine when the oil has lost its ability to protect the engine and needs to be replaced.

- Preventing Corrosion: A sufficient TBN helps prevent corrosion of engine parts, ensuring a longer engine life and reliable performance.

Understanding Total Acid Number (TAN)

TAN is a measure of acidic organic constituents that are present in lubricants detected by means of a basic reagent (potassium hydroxide or KOH). TAN is the quantity of base, expressed in milligrams of potassium hydroxide, which is required to neutralize all acidic constituents in 1 g of sample.

For used oil, TAN can increase as a result of the oxidation process that occurs during the service of lubricating oil.

Why is TAN important?

- Oil Degradation Indicator: An increase in TAN signifies the oxidation and degradation of the oil. High TAN values suggest that the oil has been in use for a long time and is becoming acidic, which can harm the engine.

- Engine Wear Prevention: Monitoring TAN helps in detecting oil breakdown early, thus preventing damage to engine components due to acidic conditions.

- Maintenance Planning: Regularly checking TAN allows for better planning of oil changes and maintenance, ensuring that the engine runs smoothly without unexpected breakdowns.

Why Both Indicators are Important?

- Complete picture: TBN and TAN provide complementary information. TBN shows the oil's ability to neutralize acids, while TAN indicates the level of acids already present. Together, they give a comprehensive picture of the oil's health.

- Optimal Oil Change Intervals: By tracking both TBN and TAN, one can determine the optimal intervals for oil changes. When TBN drops to a critical level or TAN rises significantly, it indicates that the oil should be replaced.

- Engine Protection: Maintaining the right balance between TBN and TAN is crucial for protecting the engine from wear, corrosion, and deposits, which enhances the overall reliability and lifespan of the engine.

In practice, both TBN and TAN measurements are necessary for preventive maintenance in engines, particularly in heavy-duty or high-performance applications.

By using TBN and TAN data, maintenance teams can make informed decisions about oil change intervals. This can potentially extend the oil's usable life, reduce unnecessary oil changes and therefore save costs while reducing environmental impact.

If you are interested in learning more, please contact our technical advisor or sales representative.

Back to top