Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Enilive newsletter.

Eni Lube Finder

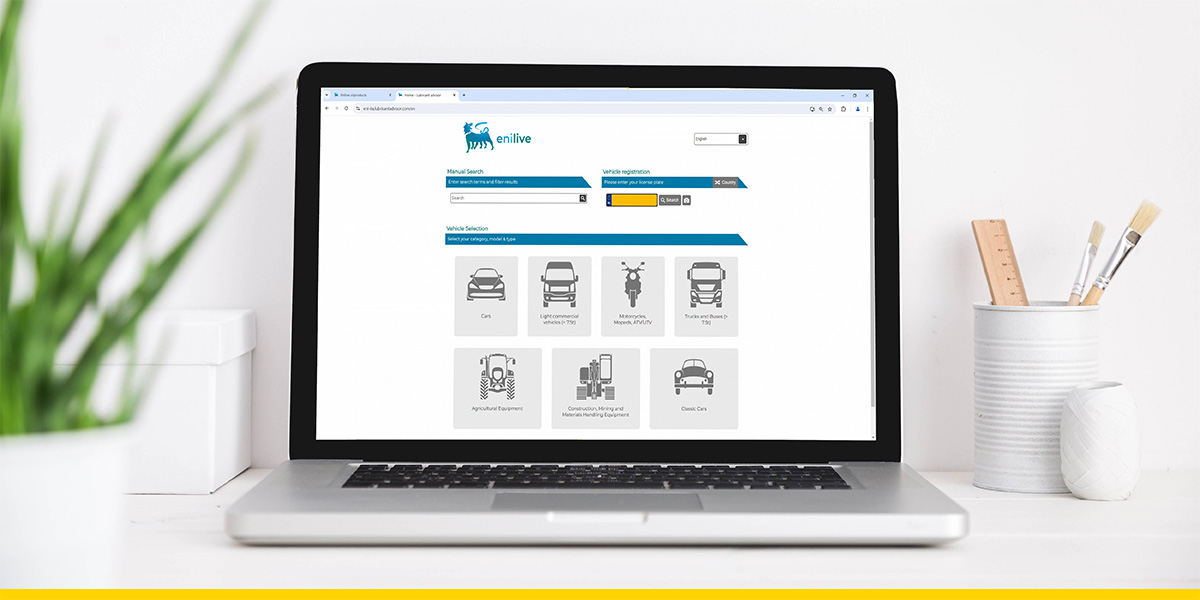

Use our Eni Lube Finder to find the best performing lubricants for your vehicle.

Click here for the Eni Lube Finder

Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Enilive newsletter.

All Material Safety Data Sheets on one website

Eni has drawn up a Material Safety Data Sheet in the national language for all its products. All material safety data sheets can be found on one central website:

msds.eni.com

On this site, you can choose your language and download the MSDS by entering the Commercial (product) name or the SDS code or SAP code of the Eni product.

Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Enilive newsletter.

‘It is much more than a job, it is a passion and a life style’

Henning Hofstad is product manager at Eni importer NDI Norge AS in Norway. In his spare time, he helps his son and his motor sport mates with their motocross hobby. This is where his passion for ENI products and for motorsport meet.

“Eni is a beautiful brand with nice people, high quality products, an appealing logo and a magnificent history. Eni was founded in 1926 (!)as AGIP", says Henning, who has been working with Eni products since 2007. The last eight years at Eni Importer NDI Norge AS, where he deals with lubricants for cars, motorcycles, trucks, earth moving and agricultural machines, industrial equipment and marine. “When people in the branch see me, they connect me to Eni and the logo.”

Read the full story here (PDF)

****

Case Story: Car company G.J. van Leenen

‘Eni oil has been used for all Saabs since 1988’

Car company G.J. van Leenen specialises in the Swedish Saab. But the engine oil has come from Italy for decades. Proprietor Gerrit Jan van Leenen chose Eni at the end of the eighties. “After trying a few other brands, I was looking for an exclusive top quality product."

At the moment there are no fewer than 39 Saabs for sale, repair and/or maintenance in and around Delft. The car company is also known by Saab lovers as Saab Delft. “From day one, my goal has been to keep my customers' Saabs at the highest possible level. But without customers having to break the bank.”

Eni's engine oils are an important instrument in this, emphasises Gerrit Jan van Leenen: “In the 31 years I've worked with Eni, the lubricants have never let me down. And we see cars with very high mileages in the workshop. It's one less worry when you know that the oil is consistently good.”

Thanks to the Eni range, the Saab specialist can service all cars with three types of engine oil: ENI i-Sint 10W-40, ENI i-Sint 5W-40 and ENI i-Sint 5W-30. “From Saabs from the 70's to the modern models with GM engine technology; all types are filled with Eni. Of course we also use Eni's brake fluid.”

In his spare time, Gerrit Jan van Leenen races a historic Lotus Cortina. “With AGIP stickers, because I use Eni Sport 10W-60 to keep the finely tuned 170 hp 1600cc four-cylinder engine in top shape. Want to know how I got to know AGIP? Through the partnership with the Ferrari F1 team in the 70s and 80s. So it was immediately clear to me I was looking at a top quality product.”

****

Case story: Knegt Quality Tractors

All Knegt tractors are filled with Eni lubricants

Knegt Quality Tractors is the only Dutch manufacturer of compact tractors. Originally developed for the equestrian circuit, a Knegt tractor is now the Dutch answer to applications in garden and forestry, gardeners, leisure and sports facilities.

Jeroen van Eerd, director and founder, talks about the origin of the company and the relationship with Eni. 'More than 15 years ago I noticed that there was no affordable compact tractor for the equestrian market. I decided to research in China and after a long search I came into contact with a factory that could supply the parts for a compact tractor that we could assemble in the Netherlands. The first shipment was exciting, but this soon turned out to be a good move. Over the years we have further developed the tractors. There was no discussion about one thing, the tractors had to be filled with Eni's oil. We have now grown to a European company and we are still, satisfactorily, filling every tractor with Eni via Oliehandel Schippers.

Racing team Kuypers

Besides running a successful business, there is fortunately still time for hobbies. With racing team ‘Team Kuypers’ we proudly drive around with Eni lettering on our cars. We also hope to achieve our successes here!'

www.knegt-international.nl

Click here for the full range of Agri products

Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Enilive newsletter.

In order to choose the best motor oil the manufacturer's recommendations should always be followed.

To identify the most appropriate lubricant it is therefore necessary to:

- Consult the section in the vehicle's maintenance guide concerning lubrication

- Identify the manufacturer's suggested viscosity level (e.g. 5W-30, 15W-40, etc)

- Identify the performance specifications required by the manufacturer (e.g. ACEA A3/B4, VW 505.00, etc)

- Choose among the Eni product range the lubricant that can guarantee the viscosity and the strict specifications of constructors.

Or you could log on to our search engine (lube finder) by clicking here, enter the vehicle model and you will find the right Eni lubricant for your car.

When do I need an oil change?

Regular oil changes ensure greater engine protection and better operation. The frequency of the oil change is indicated in your car’s maintenance manual and varies according to use (for example, predominantly urban use will more frequent oil changes). It is crucial to check your oil level frequently.

What is the ideal oil level?

- the oil level should never exceed the stated maximum indicated on the dipstick

- you should check the oil level when the engine is cold

- do not travel long distances with the level close to minimum

Can oils can be mixed?

Oils of different brands can be mixed as long as the viscosity grade and performance specifications are the same.

Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Enilive newsletter.

Why use FAST

An analysis of operational loads is indispensable for the early detection of any malfunctioning of machinery or the term of the useful life of the oil, enabling the crew to act quickly before serious damage is caused. To meet the needs of the customers, Eni offers the FAST service "Fast Analysis System Test" which provides:

- certainty of the results obtained using the most modern equipment;

- rapid analysis reports;

- a team of qualified technicians for diagnosis and comments on each analysis report;

- ease of use;

- the possibility to to schedule oil analysis;

- a database of results that can be checked directly by the customer on the web site;

- the possibility to obtain charts and comparative tables of historical results;

- traceability of the sample from arrival in the laboratory to the issue of the test report.

The kit consists of a practical case containing the material necessary to take 12 samples and arrange for safe shipment.

The laboratory

The analytical laboratory at the Eni Research Centre in San Donato Milanese, uses cutting-edge equipment and highly qualified staff and is ISO 9001:2008 certified.

A full range of controls

To determine with certainty the efficiency of the load, selected tests are performed in line with the product and the application:

- Group A for the main slow engine oils and those for auxiliary engines running on heavy fuel oil or diesel fuel;

- Group B for oils for steam turbines, for the main reduction gearboxes, propeller shafts and hydraulic systems;

- Group C heat transfer system oil.

A good quality lubricant increases engine efficiency and extends its life considerably. Even if the car travels a few kilometers it is highly recommended to perform an oil change once a year. Besides the oil, it is also advisable to replace the oil filter at least every two changes. There is obviously a cost, but taking care of your car regularly, will significantly prolong its life.

Respecting the environment

The oil used in internal combustion engines becomes a hazardous waste. If disposed of incorrectly or used improperly, it can be highly polluting. If spilled on the ground, for example, it can reach the water table and pollute drinking water. If it is dispersed in water it will create a thin, impermeable film that prevents flora and fauna from breathing. Just to give you an idea of how damaging it can be, just 4 liters of used oil, the equivalent of an ordinary oil change for a car, if spilled into the sea would pollute an area the size of a football field.

A more efficient car

To function properly, an engine needs to be permanently lubricated. Lubrication reduces friction between moving parts and limits wear that can affect the engine. The lubricant also serves to cool the mechanical parts and to protect the internal surfaces from corrosion, as well as maintaining the cleanliness of the engine and facilitating the sealing of the piston rings. A properly maintained engine will give you optimum performance.

Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Enilive newsletter.

Which are the functions of a lubricants?

A lubricant may have several functions. The main ones are:

- Keep surfaces separate under all loads, temperatures and speeds, thus minimising friction and wear

- Act as a cooling fluid removing the heat produced by friction or from external sources

- Remain adequately stable in order to guarantee constant behaviour over the forecasted useful life

- Protect surfaces from the attack of aggressive products formed during operation

- Show cleaning capability and dirt holding capacity in order to remove residue and debris that may form during operation.

How is a lubricant made?

The formulation of a lubricant is made up of base oils and additives that combine to determine behaviour when in use, both in terms of performance and in terms of duration.

The final quality of lubricating oil usually depends on the quality of the base oils used, which are generally distinguished as either:

- mineral oils: obtained from the distilling process in the refining of crude oil

- synthetic oils: which are derived from particular physical/chemical laboratory treatments

Which are the main properties of a lubricant?

The main properties of lubricants, which are usually indicated in the technical characteristics of the product, are:

- Viscosity

Viscosity describes the flow behaviour of a fluid. The viscosity of lubricating oils diminishes as temperature rises and consequently is measured at a given temperature (e.g. 40°C). - Viscosity index

The viscosity index is a characteristic used to indicate variations in the viscosity of lubricating oils with changes in temperature. The higher the level of the viscosity index, the lower the variation in viscosity at temperature changes. - Pour point

The pour point refers to the minimum temperature at which a lubricant continues to flow. Below the pour point, the oil tends to thicken and to cease to flow freely. - Flash point

The flash point is the minimum temperature at which an oil-vapour-air-mixture becomes inflammable.

Which are the benefits of synthetic base oils lubricants?

- Lower level of volatility to a comparable level of viscosity (which leads to lower consumption during use)

- Higher viscosity index (a wider temperature gap)

- Greater chemical stability at high temperatures (longer useful life)

How to choose the right engine oil?

In order to choose the best motor oil the manufacturer's recommendations should always be followed. To identify the most appropriate lubricant it is therefore necessary to:

- Consult the section in the vehicle's maintenance guide concerning lubrication

- Identify the manufacturer's suggested viscosity level (e.g. 5W-30, 15W-40, etc)

- Identify the performance specifications required by the manufacturer (e.g. ACEA A3/B4, VW 505.00, etc)

- Choose among the Eni product range the lubricant that can guarantee the viscosity and the strict specifications of constructors.

Is this the right Eni engine oil for the car in the workshop?

The right engine oil to be used is given by the proper combination of viscosity and specification profile required by the OEM. While there are various engine oils in the market the first step for the user is quite simple, follow the prescription of the car’s manual. As an alternative consult the Eni Lube Finder by using your vehicle registration plate or by searching for your vehicle. The Eni Lube Finder will recommend the engine oil to be used. In case of doubt you can always contact our Eni technical support or our local distributors.

Can engine oil with the latest specifications be used in vehicles for which an older specification was prescribed?

There is not a general rule. While this is true for example for the API categories which are backward compatible, this is not true for the ACEA categories, for example the C5 category of ACEA is not backward compatible with the other C categories.

For the OEM specification the same principle is valid, there is not a general rule, one needs to know the single specification and follow the indication of the OEM. The best advice we can give is to follow the user’s manual or ask Eni personnel for technical support.

What are the ACEA oil Sequences?

ACEA is the European Automobile Manufacturers' Association and the organization that represents the 15 most important European motor vehicle manufacturers. Among the activities of ACEA there is the definition of the engine oil specifications, so called ACEA Oil Sequences. The sequences, which are updated every few years in order to keep in consideration the latest engine technology development, set the standard for the engine oil. The ACEA oil sequences provide 3 different engine oil categories identified by a letter, each category has different classes, identified by a number, each class meets the requirement of a specific engine.

The different ACEA categories are:

A/B: gasoline and diesel engine oils, suitable for passenger cars without exhaust treatment device.

·A5/B5 offer higher fuel economy due to the lower level of HTHS and need to be used only in the engine which are designed for it.

·A3/B3 and A3/B4 offer lower fuel economy but can provide better protection in some types of engine

C: Catalyst compatibility oils, suitable for passengers cars with exhaust treatment device. In this category there are five different classes:

·C1 and C2 offer better fuel economy due to the lower HTHS, C3 and C4 have higher HTHS

·C1 and C4 are low SAPS oils while C2 and C3 are mid SAPS oils.

·C5, which is the last introduced category, offer very high fuel economy due to the lower level of HTHS and needs to be used specifically in engines designed for it.

E: Heavy Duty Diesel engine oils, suitable for heavy duty engine. In this category there are four different classes.

·E4 and E6 offer longer drain interval while E7 and E9 offer medium drain interval

·E6 and E9 can be used in engines which require limited SAPS level including the Euro VI engines, while E4 and E7 present higher SAPS level and meet the requirements till Euro V engine.

SAPS is referred to the content of Sulphated Ash, Phosphorus, Sulphur, the content of SAPS is important for the compatibility with the exhaust after treatment device.

HTHS stands for High Temperature High Share which refers to how thin the oil film is in running conditions.

Are you interested in Eni lubricants? Contact us or one of our distributors, or subscribe to the Eni newsletter.